Fire extinguisher maintenance is not just a “nice to have” for your home or business. It is a life-safety requirement that helps ensure your fire extinguisher is essential, operable, and available for use the moment a small fire happens. Beyond safety, it also supports compliance and helps keep your property safe, especially in regulated environments like commercial kitchens or any commercial fire risk setting.

If you have ever wondered what fire extinguishers need, how often maintenance needs to happen, or whether your team can handle it internally, this guide is your playbook. We will cover what maintenance and inspection really mean, what standards like NFPA 10 and OSHA require, the key steps in servicing, and how to document everything with a clean inspection tag and log.

What Is Fire Extinguisher Maintenance?

Fire extinguisher maintenance is a thorough examination and service process designed to confirm the unit will work when you need it. It is different from monthly inspections, which are primarily visual checks to confirm the extinguisher is visible, the extinguisher is located correctly, and nothing looks obviously wrong.

Maintenance goes deeper. It can include internal examination, recharging, and servicing based on the type of extinguisher and the extinguishing agent inside. The goal is simple: ensure your fire extinguisher stays in working condition throughout their lifespan, and that the extinguisher must perform as the first line of defense if you need to use the fire control device in an emergency.

Fire Extinguisher Maintenance Requirements by Standard

OSHA (29 CFR 1910.157)

OSHA sets clear expectations for portable fire extinguishers in the workplace. In general terms, extinguishers be inspected visually every month, and annual maintenance needs to be performed by trained personnel. OSHA also emphasizes recordkeeping, including documenting checks and service for at least one year. If an issue is specifically indicated by an inspection, you should address it immediately through inspection and service actions, including a recharge or repair if required.

NFPA 10

NFPA 10 is the most widely referenced standard for fire extinguisher service in the U.S., and it lays out a structured cadence:

- Annual external maintenance for most units

- Internal maintenance every 6 or 12 years, depending on the type (for example, many stored pressure fire units follow a 6-year internal maintenance cycle)

- Hydrostatic test intervals that vary by cylinder design and agent type, commonly ranging from 5 to 12 years

- Guidance for recharge, refill, replacement parts, and end-of-life considerations like expiration and lifespan

If you want a deeper overview of equipment categories, check this internal resource on types of fire extinguishers, since maintenance requirements often depend on the types of fire extinguishers and the hazard class they are designed for.

What Does Fire Extinguisher Maintenance Involve?

A proper maintenance visit typically includes these key steps, completed in a consistent, repeatable way:

✅ Checking pressure and gauge: Verify the pressure gauge is in the green zone for units equipped with a gauge, and confirm there are no signs of high pressure issues or loss of pressure.

✅ Examining hose, nozzle, seals, and safety pin: Inspect the nozzle for cracks or obstruction, confirm the tamper seal is intact, and verify the pin is secure and not bent.

✅ Inspecting for rust, dents, corrosion, or leaks: Look for corrosion (especially around seams and base rings), a dent in the cylinder body, or any leaking around the valve assembly.

✅ Ensuring label and instructions are intact: Confirm the label on the extinguisher is legible, and the instructions are not worn, peeling, or missing.

✅ Confirming proper weight/fullness: A weight check can catch slow leaks or partial discharge, especially on cartridge or stored pressure fire models.

✅ Cleaning and repositioning if needed: Make sure the extinguisher is visible, mounted correctly, and not blocked or likely to be obstructed.

✅ Updating maintenance tag: Add date, initials, service type performed, and next due date on the inspection tag.

For operations teams building SOPs, this is where “inspect and maintain” becomes a measurable process rather than a vibe. The objective is performing the proper maintenance consistently, so the fire extinguisher does not fail during a local fire event.

Types of Maintenance Services

Monthly Visual Inspection

A monthly fire extinguisher check is usually performed by internal staff after basic training. This inspection of your fire extinguishers focuses on fast, high-signal checks:

- Confirm the extinguisher is located where it should be

- Ensure the extinguisher is visible and accessible

- Verify pressure is normal on the pressure gauge

- Check for obvious damage, corrosion, leakage, or tamper evidence

- Confirm the pin and tamper seal are intact

This is also when teams commonly inspect for missing parts like a nozzle cap or signs someone tried to tamper with the unit.

Annual Maintenance

Annual maintenance is typically handled by a certified fire technician, often through a fire protection company. They will inspect more thoroughly, follow the service manual guidance, perform testing and verification, and handle minor repairs. The technician also updates the inspection tag to keep documentation audit-ready. If you are working with a licensed fire extinguisher maintenance company, they will usually include the recordkeeping workflow as part of the service.

Internal Maintenance (Every 6/12 Years)

Internal maintenance is more involved and depends on the type of extinguisher. Many dry chemical units require internal work at set intervals (commonly every six years for stored-pressure units). The extinguisher is taken out of service, disassembled, and inspected internally. The technician may:

- Perform internal part inspection

- Check the valve stem and internal components

- Confirm the extinguishing agent condition (for example, dry chemical consistency)

- Replace seals and, if needed, replace the valve

- Recharge or refill the agent and pressurize to spec

- Reassemble the unit and verify it is operable

This is also where you may see chemical details like phosphate blends or sodium bicarbonate referenced depending on the agent type, especially for dry chemical extinguishers.

Hydrostatic Testing

A hydrostatic test is a pressure test of the cylinder to confirm it can safely contain operating pressure. Intervals vary depending on the type of extinguisher and design, typically ranging from 5 to 12 years. This is critical for life safety because a compromised cylinder can be dangerous. Hydrostatic testing is commonly required around milestone timeframes like twelve years for some models, and you may see rules like every twelve years for specific designs.

Who Can Perform Fire Extinguisher Maintenance?

Here is the practical breakdown:

Monthly inspections

Trained staff can inspect, document, and escalate issues. They should know how to inspect properly, what “pass vs fail” looks like, and when to trigger service.

Annual + internal maintenance

This is generally the lane of certified fire professionals or a licensed fire provider. You will often see this handled by a licensed fire extinguisher maintenance company with technicians trained on compliance.

Local requirements

Requirements vary by local code and the AHJ (Authority Having Jurisdiction). When in doubt, align with your local fire department guidance and whatever the local fire code enforces.

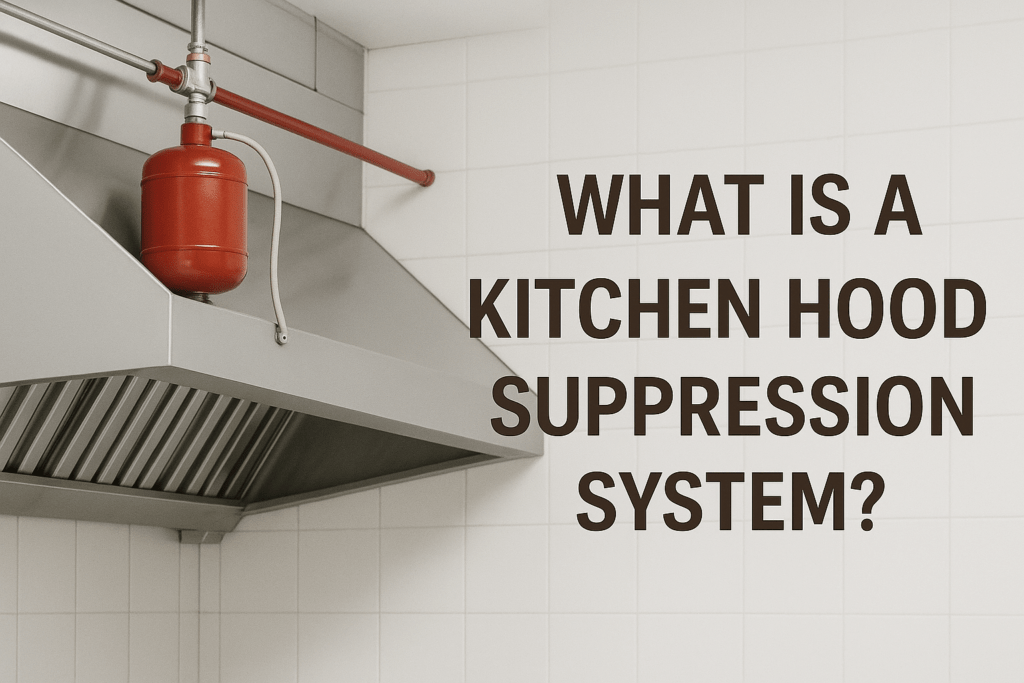

If you are building a full compliance ecosystem, it also helps to align extinguisher care with broader systems like sprinklers and alarms. For example, you can cross-train teams by linking resources like how do fire sprinklers work and how often do sprinkler systems need to be inspected into your internal safety hub.

Fire Extinguisher Maintenance Log and Documentation

Documentation is not optional if you want to stay compliant. OSHA and nfpa guidance both expect records of maintenance and inspection, stored in a paper or electronic format. A clean log should include:

- Date

- Service performed (inspection, annual maintenance, internal maintenance, hydrostatic test, recharge)

- Technician name and signature (or initials)

- Next scheduled maintenance date

This log is your defensible proof that extinguishers be inspected regularly, and that your extinguishers are in working condition across locations. It also helps track trends like recurring corrosion, damage, or misuse that might shorten lifespan.

For teams that want a tactical checklist format, this related guide can plug into your training workflows: fire extinguisher inspection checklist. It pairs well with a policy that defines fire extinguisher inspection and maintenance responsibilities by role.

Fire Extinguisher Maintenance Tips

Use a digital log with reminders

Set calendar reminders for annual service and hydrostatic intervals. This keeps maintenance needs visible and prevents last-minute compliance scrambles.

Standardize inspection language

Train staff to use consistent terms like inspect, inspection, and inspection and service notes. Consistency makes audits smoother and avoids “he said, she said” documentation gaps.

Color-code by types

Color-code storage locations based on types of fires risk and the type of extinguisher assigned. This reduces user error during a small fire and improves response time.

Train more than one person

Avoid single-threaded coverage. Train multiple staff to inspect and maintain processes monthly, especially in multi-site ops.

Validate visibility and access every month

Your monthly check should confirm the extinguisher is visible, not obstructed, and mounted correctly. A blocked fire extinguisher is basically a decorative object.

Escalate fast when issues are found

If pressure is low, there is a dent, corrosion, leakage, a broken tamper seal, or missing nozzle parts, escalate to fire extinguisher service immediately. Do not wait for annual maintenance.

Align extinguishers with alarms and sprinklers

A mature safety program covers extinguishers, alarms, and suppression systems. If you also manage alarm compliance content, link education pieces like what is a fire alarm system, types of fire alarm systems, and even response actions like how to reset fire alarm system to create a cohesive fire protection narrative.

Conclusion

Fire extinguisher maintenance is the operational difference between “we own equipment” and “we are prepared.” With the right maintenance and inspection cadence, proper documentation, and a qualified certified fire provider for annual and internal servicing, your fire extinguisher stays ready to stop a small fire before it becomes a serious incident.

Bottom line: proper maintenance supports life safety, strengthens compliance posture, and reduces the risk of costly failures. If your team treats the fire extinguisher as a true first line of defense, you are building a safer, more resilient environment, whether it is for a home or business.